多层PU智能切割机器人(S1816系列)

Multi-layer PU intelligent cutting robot(S1816)

|

规格

|

型号

|

|

单横梁单头

|

S1816DKZ

|

|

单横梁双头

|

S1816DSKZ

|

|

双横梁双头

|

S1816SSKZ

|

|

双横梁四头

|

S1816S4KZ

|

|

D:单机头 K:冲孔 Z:自动送料 S:双头/双横梁

|

|

标配:空压机+储气罐+吸风泵

|

单横梁单头S1816DKZ 单横梁双头S1816DSKZ

双横梁双头S1816SSKZ 双横梁四头S1816S4KZ

省时:

·无需制作刀模,节省制作刀模的时间。

No need to make a die, saving time in making a die.

·规则文档及不规则文档皆可按需全自动排版。

Simple shape and complicated shape can be fast nesting as required.

·直接在机器上控制所有微调功能,包括图档自动优化功能。

All fine tuning can be made with control penal on the machine.

省人:

·无需制作刀模,节省制作刀模的人工。

No need to make a die, saving labor for making a die.

·只需一人排版操作,可同时操作多台机器,一台机器至少可节省2个工人。

Only one person typesetting operation can operate multiple machines at the same time, saving at least 2 workers in one machine.

·操作简单,实用性强,只需一天的学习就可以完全独立作业。

Easy to operate, just learn one day and learn completely.

省料:

·自动排刀算料,提高5%以上的材料利用率。

Automatic pattern layout,increase material utilization by more than 5%.

·间距最小化排版,即排即出结果。

Minimum distance between pieces,instant result.

·分区域避开瑕疵自动排版。

Hierachical region avoid flaw automatic nestting.

|

产能评估/Capacity assessment

|

|

材料

|

层数

|

10H/刀

10H/knife

|

10H/片

10H/pieces

|

|

|

切割16层

|

约9000刀

|

约144000片

|

|

|

切割16层

|

约9000刀

|

约144000片

|

|

|

切割8层

|

约11000刀

|

约88000片

|

|

|

切割4层

|

约9000刀

|

约36000片

|

|

|

切割6层

|

约9000刀

|

约54000片

|

|

|

切割8层

|

约9400刀

|

约75200片

|

功能优势

1. 集多层高效裁切、智能全自动排版、全自动传送、可连续作业等功能为一体,可满足批次多、单量少的鞋业、箱包行业、汽车脚垫行业、家具行业等行业的切割需求。

2. 使用双驱动进行工作,稳定性更强,精准性更高。

3. 无需刀模,节省制作刀模的人工和时间,电脑操作与切割机同时进行,即传即切,一次性可切割1~20层PU,比传统单层切割机生产效率提升1~20倍。

4. 需频繁更换刀具及调节刀深,便可切割任意形状、任意层数、任意厚度的PU材料,个性化交互工作功能,使排版、切割、收料同时进行,最大限度调高设备工作效率。

5. 十年研发经验专业团队独立自主研发的自动排版切割系统,最大化满足PU的自动排版切割需求,高效提高皮料利用率。

6. 高度集成化多功能机头,可同时完成切割、冲孔、绘图、打标工序。

7. 针对制鞋行业,可精准高效裁切不同码数的鞋子,裁切记号齿内刀不过切。

8. 精确裁切箱包中有内窗、有拉链窗、有剪口、有贴合的多层材料的位置。

·技术参数

|

技术参数/型号

Technical

parameters/models

|

S1816DKZ

(单横梁单机头)

|

S1816DSKZ

(单横梁双机头)

|

S1816SSKZ

(双横梁双机头)

|

S1816S4KZ

(双横梁四机头)

|

|

切割面积(mm)

Cutting area

|

1800*1600

|

|

外观尺寸

Overall dimension

|

2840*2240*1300

|

|

工作特性

Operation

properties

|

电脑操作与切割作业同时进行,快速完成数据传输

Computer operation and cutting machines can be used simultaneously for quick data transmission capable of continuous operations

|

|

切割速度

Cutting speed

|

1mm/s ~ 1200mm /s

|

|

切割厚度

Cutting thickness

|

0.1mm ~ 30mm(可切割1~20层PU)

0.1mm ~ 30mm(Can cut 1~20-layer PU)

|

|

切割材料

Applicable material

|

人造革、超纤、纺织布艺、

海棉贴合纺织品、灰板、碳纤维芳纶纤维等复合材料、各类脚垫、EVA贴合材料等

Artificial leather, microfiber, textile fabrics, sponge-bonded textiles, grey boards, Composite material such as carbon fiber aramid fiber, various types of foot pads, EVA laminating materials and other materials

|

|

切割精度

Cutting tolerance

|

±0.2mm

|

|

切割圆形直径

Minimum circle

|

≥3mm diameter

|

|

振动刀头

Vibration blade

|

振动频率达18000次/分钟

Vibration cutter head motor at 18000rm

|

|

定位方式

Positioning device

|

十字激光线、CCD定位

laser light , CCD position registration

|

|

固定方式

Fixed mode

|

真空吸附固定

Vacuum adsorption

|

|

指令系统

Directive system

|

HP-GL兼容格式,软件分辨率:0.025、0.01、0.1、1

|

|

兼容软件格式

Format compatible

|

兼容软件格式AI、Autocad、Coraldraw、Photoshop、蒙泰、DXF、PLT

|

|

传输接口

Transmission

interface

|

RJ45网口,可一对多和多对一通讯

RJ45 LAN port, able to connect several machines from one computer, or several computers to one machine.

|

|

缓冲区容量

Buffer capacity

|

4GB

|

|

自动送料

Automatic feeding

|

可选配多层送料架

With multi-layer feeder

|

|

工作电压/频率

Supply voltage

|

AC 220V±10% 50/60 ±1Hz power:

MAX 3KW

|

|

吸风泵电压/频率

Suction pump

voltage

|

三相 AC 380V ±10% 50/60 ±1HZ 功率 8.5KW

AC 380V ±10% 50/60 ±1HZ power 8.5KW

|

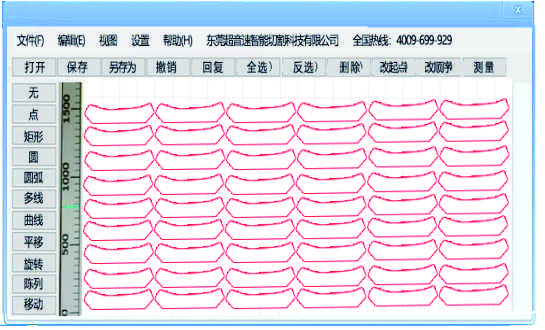

自动排版软件

Automatic nesting softwarem

【软件说明】超音速自动排版软件是一款全自动皮革排版软件,用户通过软件可快速对规则文档、不规则文档进行排版,即排即出结果,从排版算刀到裁切,一步到位,节省时间。

【Software description】The supersonic automatic typesetting software is a fully automatic leather typesetting software. Users can quickly typeset the regular documents and irregular documents through the software, that is, the results are discharged, from the typesetting knife to the cutting, one step in place, saving time.

【适用范围】适用于批次多、单量小、交期短、多轮次生产模式的鞋业、箱包行业、汽车脚垫行业、家具行业等行业企业的切割需求。

【Scope of application】It is suitable for the cutting needs of enterprises in the footwear industry, luggage industry, automobile foot pad industry, furniture industry, etc. with many batches, small quantities, short delivery times and multiple rounds of production mode.

【优点】·具备DT转档功能,支持多种文档格式转换,具备CAD修改文档、优化功能。

DT file transfer function, support multiple document format conversion, CAD modification document, optimization function .

自动排版,自动接码,自动插刀,有效提升材料利用率,节省时间,可实现轮次化生产需求。

Automatic typesetting, automatic code selection, automatic tool insertion, effectively improve material utilization, save time, and achieve round-robin production demand .

·可手动扩展排版模式,人为控制用量,也可做到大小码接刀及同材料插刀,使排版换码接料更合理。

Manually expand the layout mode, you can control the amount manually, and you can also use the size code to connect the knife and the same material to insert the knife, so that the typesetting code is more reasonable.

规则文档自动排版 Rules document automatic typesetting

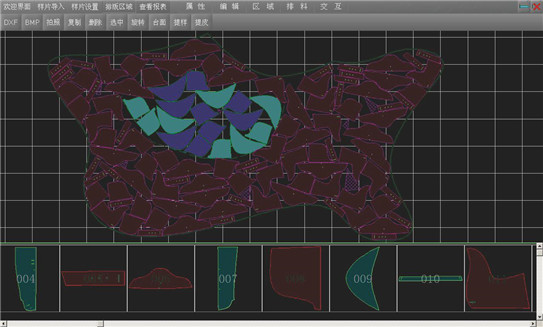

不规则文档组合排版 Irregular document composition typesetting

分区域避开瑕疵自动排版 Hierachical region avoid flaw automatic nestting.

(需另购相机和投影仪)

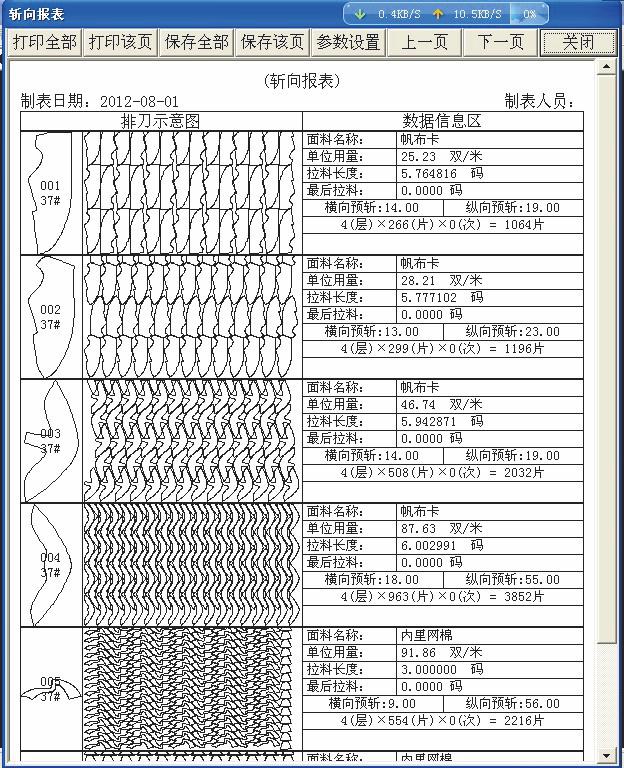

自动排刀算料系统

Automatic pattern layout system

提高5%以上的材料使用率,节省成本。

Reduce at least 5% wastage to save production cost.

可对同种材料进行识别后进行自动组合排料,改变传统的手工组合所带来的不同材料组合而

导致数据出错,减少损失,省料、省时、省人。

The same kind of material can be identified and then automatically combined to discharge, change the traditional combination of different materials caused by the manual combination of data, resulting in data errors, reduce losses, save material, save time, save people.

精确算料订料,降低材料采购和库存成本。

Accurately count material and reduce material procurement and inventory costs.

为裁断下料生产提供严格、透明的管理流程,减少浪费,提高管理执行力度。

Provides strict and transparent management procedures for cutting production, reduces waste, and improves management execution.

操作简单,实用性强,一个会电脑操作的员工,只需一天的学习就可以完全独立作业。

With simple operation and strong practicality, one will operate the staff and only complete one day's work.

(除此之外,我们的主推产品有纸样切割机、鞋样切割机、电脑裁皮机)